In this blog:

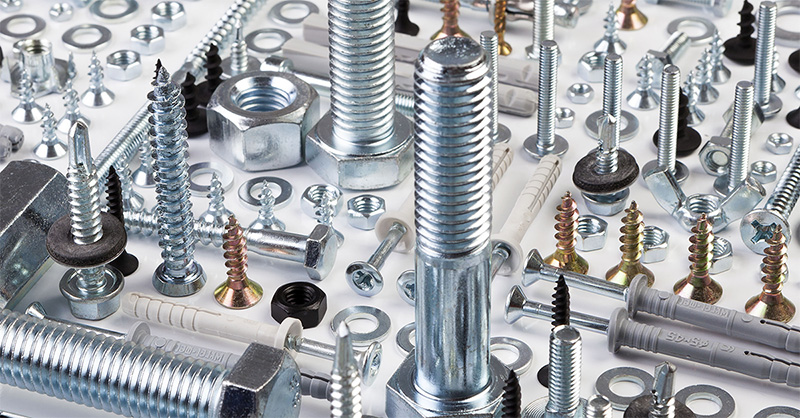

Heavy machinery applications demand durability, precision, and reliability from every component used, especially when it comes to fasteners. Fasteners are the unsung heroes of machinery, holding everything together under extreme conditions and ensuring that all parts function seamlessly.

The role of high-strength fasteners in heavy machinery

High-strength fasteners are engineered to provide strength and endurance, capable of withstanding high pressures, vibrations, and varying temperatures. These specialized fasteners are used in applications ranging from construction equipment and agricultural machinery to heavy-duty trucks and industrial machinery. The key to their performance lies in their solid construction, material quality, and precision engineering.

The primary role of high-strength fasteners in heavy machinery is to ensure structural integrity and operational reliability. They are designed to lock components in place securely, preventing loosening due to vibration, thermal expansion, or operational stress. This reliability is critical in demanding environments where equipment failure can result in significant downtime, operational delays, and safety hazards.

Different types of high-strength fasteners

Royal Brass and Hose carries an extensive product range of fasteners, including but not limited to:

-

Grade 8 Bolts and Nuts: Known for their exceptional strength and toughness, Grade 8 bolts and nuts are ideal for applications requiring high tensile strength and resistance to shear forces.

-

Grade 2 Nuts: Often used in low-stress applications, Grade 2 nuts are made from carbon steel and provide a good level of strength and ductility for light to medium-duty jobs. They are a cost-effective option for general use where high strength is not the primary requirement.

-

Grade 5 Nuts: These are medium-strength fasteners made from quenched and tempered steel. Grade 5 nuts offer a good balance of strength and ductility and are suitable for many automotive and industrial applications where higher load bearing is necessary.

-

Grade 10.9 Metric Bolts: These high-strength fasteners made from alloy steel are tempered and quenched. Grade 10.9 bolts are commonly used in automotive applications where extremely high loads and stress resistance are required. They provide superior strength compared to most other grades.

-

Lock Washers and Flat Washers: These components play a vital role in maintaining the tension in bolted joints and distributing the load evenly, thereby enhancing the joint's overall stability and durability.

-

Self-Tapping Screws: Perfect for applications where pre-drilled holes are not feasible, self-tapping screws create their own threads, ensuring a tight and secure fit in metal, plastic, or wood.

-

Threaded Rods: Offering versatility and strength, threaded rods are used extensively in construction, plumbing, and manufacturing for assembling, hanging, mounting, and bracing applications.

Learn more about the different types of fasteners in our blog: Fasteners 101: Types and Uses.

Fastener Dos and Don'ts in heavy machinery applications

DO select fasteners that match the material strength and durability requirements of your application to avoid premature failure.

DO follow the manufacturer’s torque specifications to ensure fasteners are neither too tight nor too loose, which could lead to increased wear or catastrophic failure.

DON’T reuse critical fasteners without assessing their condition, as fatigue and stretching can compromise their integrity.

DON’T underestimate the importance of the correct fastener coating, as it can greatly impact resistance to corrosion and the overall lifespan of the component.

DON'T use a fastener designed for a higher strength than recommended for a piece of equipment, it could result in catastrophic damage to the equipment.

How to choose the right high-strength fastener: an example from the field

Use case: Reinforcing a construction crane's structural integrity

Situation: In the bustling heart of a major city construction project, a crane operator named Alex oversees the lifting of heavy steel beams for a new skyscraper. The project's timeline is tight, and the machinery, especially the crane, is under constant stress from both the weight it carries and the varying weather conditions.

Challenge: After a routine inspection, Alex notices unusual vibrations and slight misalignments in the crane's arm structure. Upon further examination, it's clear that several critical bolts have begun to loosen, a potentially disastrous issue that could lead to operational failure or, worse, a safety hazard for the workers below.

Solution: To address this critical problem, Alex turns to high-strength, Grade 8 bolts known for their exceptional durability and reliability under extreme conditions. These bolts are specifically designed for heavy machinery applications and can withstand the high loads and stress the crane is subjected to.

Implementation:

Assessment: A team of engineers evaluates the crane to determine the exact specifications needed for the replacement fasteners, considering the weight it carries and the environmental conditions it operates in.

Selection: Based on the assessment, the team selects the appropriate size and type of Grade 8 bolts, ensuring they are suitable for the high tensile and shear strength requirements.

Installation: The old bolts are carefully removed, and the new Grade 8 bolts are installed, following the manufacturer’s torque specifications to the letter. Special attention is paid to the proper use of lock washers to prevent any future loosening due to vibration.

High-strength fasteners FAQs

How are high-strength fasteners graded?

Fasteners are graded based on their material and mechanical properties, including tensile strength and yield strength. For example, in the U.S., grades 5 and 8 are common for carbon steel bolts, with grade 8 being higher in strength.

What materials are high-strength fasteners made from?

They can be made from a variety of materials, including carbon steel, alloy steel, stainless steel, and titanium, each offering different levels of strength, corrosion resistance, and suitability for specific environments.

Can high-strength fasteners be used in all applications?

While high-strength fasteners are versatile, their use depends on the application's specific requirements, including load, environmental conditions, and material compatibility. It's essential to select the right fastener for the job to ensure safety and longevity.

How do I choose the right high-strength fastener for my application?

Consider factors such as the type of materials being fastened, the environmental conditions (corrosive, temperature extremes, etc.), the load (static, dynamic, impact), and any industry-specific standards or regulations.

What are the common mistakes to avoid when using high-strength fasteners?

Over-tightening, under-tightening, mixing materials that may cause galvanic corrosion, and neglecting to consider the effects of thermal expansion are common pitfalls.

Can high-strength fasteners be reused?

It depends on the fastener and the application. Some high-strength fasteners, especially those subject to critical loading conditions, are not recommended for reuse due to potential stretching or fatigue. Always inspect and assess the fastener's condition before deciding on reuse.

How do environmental conditions affect the choice of high-strength fasteners?

Environmental factors such as humidity, saltwater exposure, and chemical exposure can affect fastener performance. Material choice, such as stainless steel or coated fasteners, can mitigate these effects.

What are the maintenance and inspection recommendations for high-strength fasteners?

Regular inspections for signs of wear, corrosion, or loosening are recommended. Maintenance schedules should be based on the application's severity and the fastener manufacturer's recommendations.

Conclusion

In the demanding world of heavy machinery, the right fasteners can make all the difference in ensuring equipment reliability and longevity. High-strength fasteners from Royal Brass and Hose offer the perfect combination of durability, performance, and peace of mind, making them an ideal choice for applications where failure is not an option. Whether you're building, repairing, or maintaining heavy machinery, count on Royal Brass and Hose to provide the high-quality fasteners your projects demand.

Need help with selecting a fastener?

When it comes to fasteners, we’re trusted experts. Contact us or call 1-800-669-9650 to speak with a member of our customer service team at any of our 11 locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY).