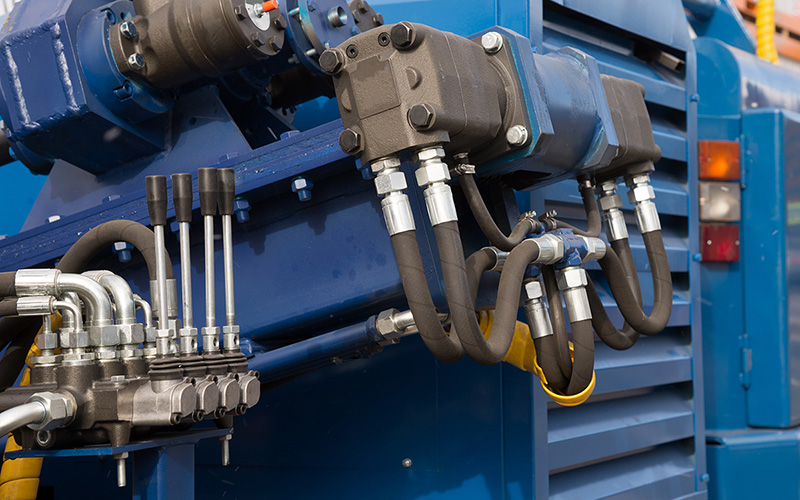

When designing or maintaining a hydraulic system, choosing the right hydraulic suction and return lines is key for optimal performance. These lines ensure the efficient transfer of fluid between components, preventing contamination, cavitation*, and system failure. In this guide, we’ll break down what hydraulic suction and return lines are, their functions, and how to decide the best options for your system.

*Cavitation happens when the pressure in a hydraulic system gets so low in certain spots that the liquid starts to form vapor bubbles. These bubbles aren’t air—they’re made from the liquid turning into vapor. As the bubbles move into areas of higher pressure, they quickly collapse, which can damage the system and make it less efficient.

What Is a Hydraulic Suction Line?

The suction line connects the reservoir to the hydraulic pump, allowing fluid to flow smoothly into the pump. Its primary function is to ensure an uninterrupted supply of hydraulic fluid under low pressure.

Key Considerations for Suction Lines

-

Material and Construction

Suction lines are typically made of reinforced rubber or thermoplastic materials that can withstand vacuum pressure. Look for hoses with flexible yet durable construction to prevent collapse under suction.

-

Internal Diameter (ID)

The ID of the suction line should be large enough to prevent cavitation and minimize pressure drops. Undersized hoses can restrict fluid flow, leading to pump damage.

-

Compatibility

Ensure the hose material is compatible with the hydraulic fluid used. Incompatibility can cause degradation and contamination.

-

Operating Temperature and Pressure

Suction lines must withstand the temperature and vacuum conditions of your hydraulic system. Always check the hose’s temperature and pressure ratings before installation.

What Is a Hydraulic Return Line?

The return line carries hydraulic fluid back from system components to the reservoir. These lines handle low pressure but need to manage high flow rates.

Key Considerations for Return Lines

-

Flow Rate Capacity

Return lines must accommodate high flow rates without causing significant pressure buildup. Select a hose with a large enough ID to handle peak flow conditions.

-

Pressure Rating

While return lines typically operate under lower pressures than other hydraulic lines, they should still be rated for system-specific conditions, especially in systems with fluctuating pressures.

-

Filtration

Installing a return line filter helps trap contaminants, ensuring cleaner fluid returns to the reservoir, prolonging system life.

-

Material Durability

Return lines often face exposure to environmental conditions. Choose hoses with abrasion and weather-resistant materials for longer service life.

How to Decide on the Right Hydraulic Suction and Return Line

Choosing the best suction and return lines involves balancing system requirements, hose specifications, and operational conditions. Here’s a step-by-step guide:

- Understand System Requirements

- Determine the operating pressure and temperature.

- Measure the maximum flow rates in both suction and return paths.

- Assess the environmental conditions (e.g., exposure to heat, cold, or chemicals).

- Select the Correct Hose Size

- Use hose ID charts to match the system’s flow rate and pressure requirements.

- For suction lines, prioritize minimizing pressure drop to avoid cavitation.

- For return lines, ensure the hose can handle maximum return flow without causing backpressure.

- Focus on Compatibility

- Verify that the hose material is compatible with the hydraulic fluid used.

- Look for hoses rated for specific fluids, such as petroleum-based, synthetic, or biodegradable oils.

- Check for Certification and Standards Compliance

- Use hoses compliant with industry standards like SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization) to ensure reliability and safety.

- Consider Hose Assembly Requirements

- Use quality fittings and connectors to minimize leaks.

- Properly secure hoses with clamps or brackets to reduce vibration and abrasion.

Common Mistakes to Avoid

Undersized Hoses

Installing a hose with a smaller-than-recommended ID can cause different issues based on whether it is a return line or a suction line:

Return Lines

- Restricts flow, creating backpressure in the return line.

- Increased backpressure leads to pressure increases upstream of the restriction.

- This can result in overheating, reduced efficiency, and damage to components.

Suction Lines

- Creates a flow restriction at the pump inlet.

- This can lead to negative pressure or vacuum in the suction line, causing cavitation at the pump.

- Cavitation can damage the pump, reduce system performance, and decrease overall system pressure.

Ignoring Pressure Ratings

While suction and return lines typically operate at lower pressures, exceeding their ratings can cause failure.

Overlooking Filtration

Failing to include a return line filter can allow contaminants to circulate, leadning to wear and tear on system components.

Hydraulic Hoses for Various Fluid Systems

Hydraulic hoses are designed to handle different types of fluids and operate in specific systems. Depending on the type of fluid and the application, selecting the right hose can make a significant difference in performance and longevity. Below, we’ll explore some common uses for hydraulic suction and return hoses based on the fluid and system types:

Water-Based Hydraulic Fluids

Water-based hydraulic fluids are often used in environments where fire resistance is a concern, such as in mining or industrial applications. Hoses compatible with these fluids must resist water absorption and maintain flexibility under low temperatures. They are commonly found in systems requiring safer, non-flammable fluids.

Shop Eaton/WEATHERHEAD H039 Suction Hose SAE 100R4

Shop Continental HR4 Suction Hose SAE 100R4

Thermal Fluid Heating Systems

In thermal fluid heating systems, hoses are exposed to high temperatures as they transfer heated fluids to maintain system efficiency. These hoses must withstand extreme heat without degrading. They are frequently used in industrial heating processes or specialized machinery like plastic molding equipment.

Shop Gates G5TB Mega Tech Extreme Heat Oil-Air Return Hose

Shop Gates MegaTech 3000 High Temp Oil-Air Return Hose

Petroleum-Based Fluids

Hoses designed for petroleum-based fluids must resist the chemical properties of oils and other hydrocarbons. These hoses are critical in applications such as oil and gas extraction, transportation, and storage, where durability and fluid compatibility are essential.

Shop GMV Global Mega Vac Return Line and Suction Low Pressure Hose

High-Pressure Applications

Some hydraulic systems, such as those in industrial presses or heavy-duty mining equipment, operate under extreme pressure. Hoses designed for high-pressure applications are reinforced to prevent failure and ensure safety in demanding environments.

Shop DANFOSS H280 High Pressure Hydraulic Hose SAE100R16

Transmission Oil Cooler Lines

Hoses used in transmission oil cooler lines are designed to handle high-temperature oil flows and provide cooling to prevent system overheating. These are commonly used in automotive and industrial machinery, where maintaining proper transmission function is crucial.

Shop Gates MegaTech250 High Temp Transmission Oil Cooler Hose

Maintaining Your Hydraulic Suction and Return Lines

-

Regular Inspections

-

Check for signs of wear, such as cracking, abrasions, or leaks.

-

Inspect connections and fittings for tightness.

-

Replace When Needed

-

Replace hoses at the first sign of damage or at the end of their service life.

-

Use OEM (Original Equipment Manufacturer) or high-quality aftermarket parts for replacements.

-

Keep the System Clean

-

Regularly flush the hydrualic sustem to prevent buildup.

-

Ensure fluid levels are maintained and contaminants are diltered out.

-

Filter Selection and Maintenance

-

Using a return line filter with an improper flow rating can create backpressure, reducing efficiency and damaging system components. Regular maintenance is essential to prevent blockages that can also lead to increased backpressure and system strain.

Choosing the right hydraulic suction and return lines is essential for a well-functioning hydraulic system. By understanding your system’s specific needs and considering factors like hose size, material compatibility, and pressure ratings, you can ensure optimal performance and longevity. Regular maintenance and proper installation further reduce the risk of system failure.

Need Help?

Contact your local Royal Brass and Hose sales representative or call us at 800-669-9650 to speak with a member of our Customer Service team at any of our locations across the Southern United States.