Choosing the right hydraulic hose for your equipment isn’t just about size or compatibility—it’s about matching the hose’s pressure rating to the demands of your system. From extremely high-pressure hoses that handle the toughest jobs to low pressure options for more routine tasks, this guide covers everything you need to know. Whether you're in construction, agriculture, or industrial maintenance, understanding the pressure capabilities of hydraulic hoses will help you ensure safety and efficiency.

Hydraulic hoses overview

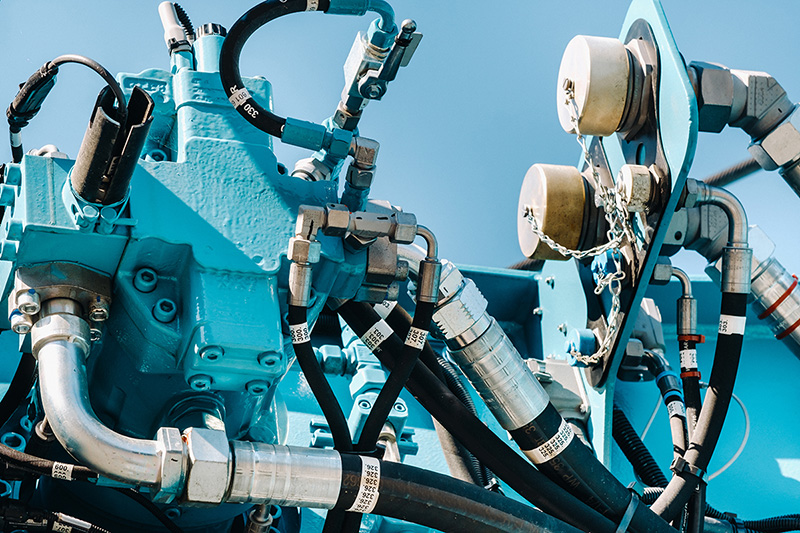

Hydraulic hoses have become the preferred choice over rigid pipes and tubes in modern hydraulic systems due to their numerous advantages:

- Cost Efficiency: Hydraulic hoses are generally less expensive to manufacture and replace than rigid pipes.

- Lightweight Design: The flexible nature of hydraulic hoses makes them much lighter, reducing the overall weight of machinery.

- Shock and Vibration Absorption: Hydraulic hoses are better equipped to absorb shocks and vibrations, which extends the life of the hydraulic system.

- Ease of Installation: Routing and installing hydraulic hoses is simpler, requiring no specialized tools or bending techniques.

- No Risk of Rust: Unlike metal pipes, hydraulic hoses do not corrode, making them ideal for use in environments where moisture or corrosive substances are present.

- Movement Accommodation: Hydraulic hoses allow for movement between components, which is crucial in mobile or articulated machinery.

- Noise Reduction: The flexible material of hydraulic hoses absorbs sound, reducing noise in high-pressure systems.

- Pressure Surge Dampening: Hydraulic hoses are designed to handle and dampen sudden pressure surges, protecting the entire hydraulic system.

Hydraulic hoses are designed to meet strict standards to endure high-pressure levels, heavy loads, and often extreme positions. Understanding the different types of hoses by their pressure ratings can help you select the right hose for your specific application.

Extremely high-pressure hydraulic hoses

These hoses are reinforced with multiple layers of spiral wires to ensure extremely high performance in the most demanding applications. They meet stringent governmental standards for safety and reliability.

Typical Pressure Range: 6000 to 10,000 PSI (414 to 690 bar)

- SAE 100R15: This high pressure hydraulic hose has a 6,000 psi operating pressure in all sizes, making it ideal for hydrostatic transmissions, snow groomers, blacktop milling machines, and off-road construction equipment.

- SAE 100R13: With a 5,000 psi operating pressure across all sizes, the SAE 100R13 hydraulic hose is used in applications such as logging equipment, agricultural equipment, injection mold machines, and mobile construction equipment.

- SAE 100R12: Operating at 4,000 and 3,000 psi, this high-pressure hydraulic hose is suitable for both biodegradable hydraulic fluids and petroleum-based fluids, often used in industrial machinery.

- Jack Hose: Specifically designed for 10,000 psi applications, this hose is crucial for body shops and fire departments that utilize hydraulic jacks.

Relevant Standards:

- ISO 18752: Rubber hoses and hose assemblies — Wire- or textile-reinforced single-pressure types for hydraulic applications.

- EN 857: Covers very high-pressure, wire-reinforced compact hoses.

- SAE 100R15: Very high-pressure hose standard.

High-pressure hydraulic hoses

High-pressure hoses are essential in applications where robust performance is required, such as construction, agricultural, and industrial equipment.

Typical Pressure Range: 3000 to 6000 PSI (207 to 414 bar)

- SAE 100R2AT: This hose is versatile, with varying psi per size, and is widely used in construction, machine tools, and agricultural applications with high temperature petroleum- or water-based hydraulic fluids.

- SAE 100R16: This hose features half the bend radius of the SAE 100R2 with operating pressures from 6,000 to 1,500 psi, making it a compact yet powerful option.

- SAE 100R17: With a consistent 3,250 psi operating pressure, this hydraulic hose is commonly found in farm equipment, offering reliable performance in demanding conditions.

- SAE 100R19: This hose handles up to 4,000 psi and is used in the plumbing of mobile and stationary hydraulic platforms.

Relevant Standards:

- ISO 1436: Also includes high-pressure classifications.

- ISO 3862: Rubber hoses and hose assemblies — Rubber-covered spiral-wire-reinforced hydraulic types — Specification.

- EN 856: Covers high-pressure hydraulic hoses.

- SAE 100R2, R9, R12: High-pressure hose standards.

Medium-pressure hydraulic hoses

Medium-pressure hydraulic hoses are used in many applications, from automotive systems to industrial machinery and cleaning equipment.

Typical Pressure Range: 300 to 3000 PSI (20.7 to 207 bar)

- SAE 100R1: Reinforced with a single braid of high-tensile wire, this hose is used on agricultural equipment and snowplows.

- SAE 100R3: This hose is used for hydraulic oil, antifreeze solutions, and in low-pressure return lines and car wash wand applications.

- SAE 100R6: This hose has varying psi by hose size and is used for hydraulic oil and automatic transmission cooler lines.

- SAE 100R5: Found in fleet applications, including airlines, lube oil lines, petroleum-based oil lines, air brake, filtration, and power steering.

- SAE J1527 and J1942: These hoses are essential in the marine market for diesel and gasoline applications, meeting Coast Guard approval.

- Pressure Washer Hose: Suitable for hot or cold applications on van- or truck-mounted equipment, providing durability and flexibility.

Relevant Standards:

- ISO 1436: "Rubber hoses and hose assemblies — Wire-braid-reinforced hydraulic types — Specification."

- SAE J517: Includes medium-pressure hose specifications.

- EN 853: Covers medium-pressure hoses with specific requirements for reinforcement and performance.

Low-pressure hydraulic hoses

Low-pressure hoses and return lines are designed for less demanding applications but still require durability and reliability.

Typical Pressure Range: Up to 300 PSI (20.7 bar)

- SAE 100R4: Used as return or suction lines for petroleum and water-based hydraulic fluids, this hose is crucial in various industrial systems.

- SAE 30R2 (Type 1 and 2): Suitable for water, glycol antifreeze solutions, diesel fuel, gasoline, and air, making it versatile for different applications.

Relevant Standards:

- ISO 4079: "Rubber hoses and hose assemblies — Textile-reinforced hydraulic types — Specification."

- EN 854: Covers hoses for lower pressure applications.

Shop hydraulic hoses

Extremely high pressure hydraulic hoses

Medium-pressure hydraulic hoses

Need Help?

If you're unsure which hydraulic hose fits your application, don't hesitate to reach out. Contact your local Royal Brass and Hose sales representative or call us at 800-669-9650 to speak with a member of our Customer Service team at any of our locations across the Southern United States.