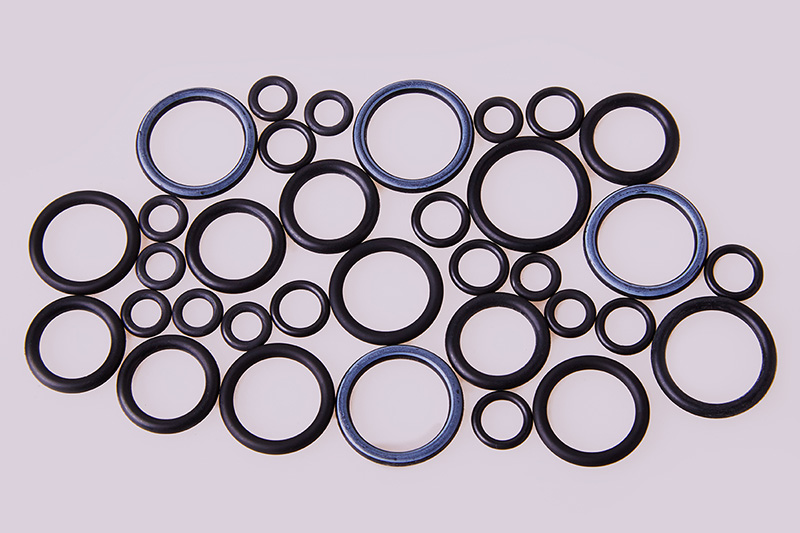

O-Rings are unassuming yet indispensable components that play a critical role in sealing applications across a myriad of industries. Their versatile nature and efficient functionality make them an essential choice for sealing solutions. However, with the plethora of O-Ring types available, selecting the right one for your specific needs can often feel like navigating a labyrinth. In this guide, we’ll equip you with the knowledge to make informed decisions regarding which O-Ring is right for your application.

Introduction to O-Rings

O-Rings are circular, loop-shaped elastomeric rings primarily employed for sealing gaps between two or more parts. They’re deceptively simple yet incredibly effective. When compressed between mating surfaces, O-Rings form a reliable barrier that prevents the escape of fluids or the entrance of contaminants. This makes them useful in countless industries and applications as diverse as manufacturing, automotive, aerospace, pharmaceuticals, and many more. Whether used to contain hydraulic fluids or maintain the integrity of delicate medical equipment, O-Rings are a tried-and-true sealing tool.

The Role of Flare-O O-Rings in Hydraulic Fittings

Flare-O O-Rings, often composed of Buna-N or Viton, are specifically designed for use in hydraulic fittings. These O-Rings provide a highly effective seal, eliminating hydraulic leaks when correctly implemented. They are particularly well-suited for SAE 37° flared tube fittings, serving as leak-proof replacements and contributing to the overall integrity of hydraulic systems.

Bonded Seal O-Rings: Bolstering Hydraulic Equipment

Bonded Seal O-Rings, often referred to as Dowty Seals or Dowty Washers, are a staple in hydraulic equipment, frequently employed as bolt seals. These seals consist of a metal outer ring and a rubber elastomer inner ring, effectively forming a gasket that provides sealing action. Their versatility extends beyond hydraulic systems, offering a reliable solution for a range of applications where rubber-to-metal or plastic bonding is necessary.

Understanding the Function and Applications of O-Ring Boss (ORB) Seals

O-Ring boss (ORB) seals play a vital role in connecting two fluid-carrying components, such as pipes, hoses, or tubing. In an ORB system, a male-threaded part is inserted into a female-threaded part, creating a mechanical seal. To ensure a fluid-tight seal, an additional nut is tightened over an O-Ring, which is positioned in a chamfered area. These seals are particularly effective in applications involving hydraulics, compressed air systems, and vacuum pumps. They offer a reliable means of joining components while preventing leakage.

Exploring Flange Seals and Their Role in Static Sealing

Flange seals are designed to provide front-face static sealing in flange connections. These seals are suitable for both internal and external pressure applications and are available in a diverse range of materials. Flange connections are commonly used in tubing applications with larger outer diameters or those subjected to high pressures. In typical scenarios, an O-Ring is utilized to seal the joint, effectively containing pressurized fluid within split-flange fittings. These fittings consist of permanent flanged heads connected to tubes, along with O-Rings and mating clamp halves. The elastomeric O-Ring is seated within a groove on the flange and mates with a flat surface on the port. Mounting bolts are used to secure the O-Ring flange onto the flange clamps, ensuring a secure and leak-free connection.

Buna-N: A Common Choice for Quick Couplings

Buna-N, also known as Nitrile, is a frequently employed material in quick couplings. This versatile material boasts resistance to solvents, oils, and water, making it suitable for various applications. It can withstand temperatures ranging from -40°F to 250°F (-40°C to 121°C), making it a resilient choice for a wide range of environments. Buna-N is commonly utilized in engines, gearboxes, and other applications, including those found in aircraft and everyday household items. Its adaptability allows for both rotary and linear movement, making it an excellent choice for face-to-face gasket-style seals or shaft seals.

Peroxide Cured EPDM: A Standard for Challenging Applications

In the realm of sealing solutions, Peroxide Cured EPDM, also known as Ethylene-propylene-diene rubber, emerges as a definitive choice, setting new benchmarks for O-Rings employed in various applications. This exceptional material not only upholds its stature in medical-grade polypropylene couplings but extends its influence across diverse industries such as automotive manufacturing and wastewater systems. Its unparalleled resistance to an array of chemicals bestows it with a unique status, rendering it invaluable in challenging environments where O-Ring durability and reliability are paramount. Remarkably, this versatile elastomer even finds its place within the confines of common household appliances due to its outstanding chemical resistance properties.

Viton O-Rings: Resilience Against Extreme Temperatures and Chemicals

Viton O-rings are prized for their exceptional resistance to extreme temperatures and various chemicals. They offer protection against ozone, oxygen, mineral oil, synthetic hydraulic fluids, fuels, aromatics, and a range of solvents and chemicals. With qualities such as excellent permeability, compression set resistance, and low gas permeability, Viton O-Rings find their niche as gaskets in fuel line system sealing applications. Additionally, other fluorocarbon compounds provide enhanced resistance to acids, fuels, water, and steam.

Kalrez® O-Rings: A Resilient Shield Against Harsh Conditions

Kalrez® O-Rings, crafted from perfluoroelastomer (FFKM), are also renowned for their resilience against chemicals and high temperatures. These robust O-Rings find extensive use in various industries, boasting an extended service life and impressive resistance to a multitude of elements. Kalrez® stands as a standout material capable of withstanding extreme temperatures and pressures while maintaining superior chemical resistance.

Silicone O-Rings: Flourishing in Dry Heat Environments

Silicone O-Ring material excels in applications characterized by dry heat. With a safe operating temperature range from -70°F to 400°F (-57°C to 204°C), these O-Rings are widely used in medical devices, food storage products, electronics, automotive manufacturing, and home repair and hardware items.

O-Ring Seals for Flared Fittings: Ensuring Precise Connections

Two primary types of O-Ring seals are employed in flared fittings, specifically those utilizing O-Ring face seals (ORFS):

ORFS Fittings

These fittings incorporate a replaceable elastomeric O-Ring seated in a groove on the fitting's face. Designed to address leakage concerns in high-pressure hydraulic systems, this configuration utilizes a Buna-N, 90 Durometer O-Ring. When the connection is tightened, the O-Ring compresses against a flat face sleeve that is brazed onto the end of a tube, forming a secure metal-to-metal seal. This design minimizes twisting of the tube and offers support during assembly.

Flare AN Seals

Also known as Flare-O O-Rings, these seals cater to 37° flare fittings compliant with SAE J514 and ISO 8434-2 standards. Predominantly made from Buna-N or Viton, the 37° flare AN seal finds its role in tubing end connections. In this arrangement, a nut is affixed to the end of the tube, which is flared using a specialized tool. The threaded nut is then inserted into a flare fitting, creating a seal that encompasses the flared tube. Flare-O seals for 37° flare fittings are particularly prevalent in aerospace, marine, and select older applications that have not transitioned to flareless tube fittings.

Conical Seals: Addressing Imperfections with Precision

Conical seals, available in aluminum, copper, nickel, and stainless steel, serve as reliable seals on the end of 37-degree flared fittings of similar dash numbers. These seals are designed to mitigate the impact of minor nicks or defects in the fitting that may compromise proper sealing. Soft annealed 37° conical seals function as crush washers on a male AN flare, enhancing the reliability of seals while safeguarding tubing and AN fittings from damage.

Conclusion

O-Rings, those unsung heroes of the sealing world, come in an array of types, each tailored to meet the unique demands of various industries. From withstanding scorching temperatures to battling corrosive chemicals, these unassuming rings play a pivotal role in ensuring that machines operate seamlessly, and fluids remain where they should. Armed with the insights from this comprehensive guide, you are now equipped to navigate the labyrinth of O-Ring types and make informed decisions that will set the stage for efficient and reliable sealing solutions across diverse applications.

Need help selecting the right O-Ring type?

Our experts have crafted several helpful resources to explore:

- Learn How to Select the Right O-Ring for Your Application.

- Learn about product performance standards in O-Ring Industry Standards and Certifications.

When it comes to O-Rings, we’re trusted experts. Contact us or call 800-669-9650 to speak with a member of our customer service team at any of our 11 locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY).