Hydraulic hose failures are a major cause of downtime at any job site requiring the use of heavy-duty machinery to complete a work project. While replacement is inevitable, following these five vital steps to prevent hydraulic hose failures can delay it from happening before it should, saving time and money.

5 Steps to Prevent Hose Failure:

- Construct the Hose Correctly

- Route the Hoses Properly

- Use an Appropriate Bend Radius

- Be Mindful of Extreme Temperatures

- Maintain Proper Operating Pressure

Step 1:

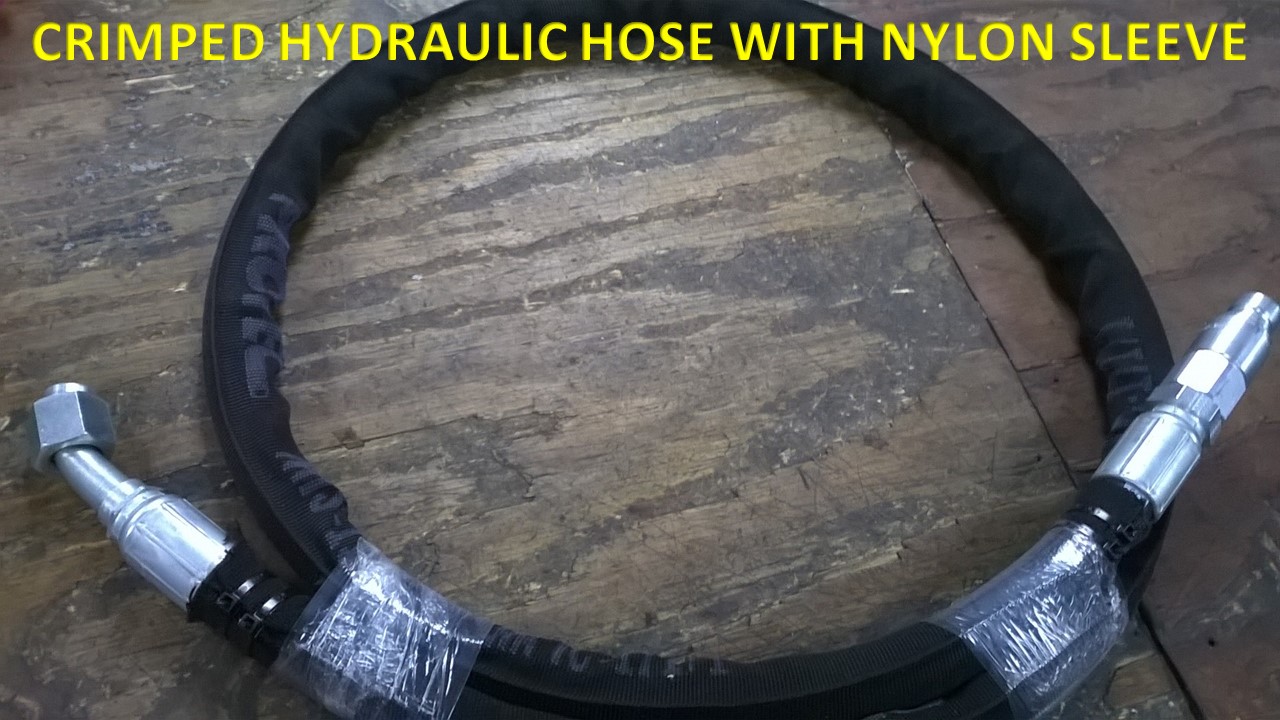

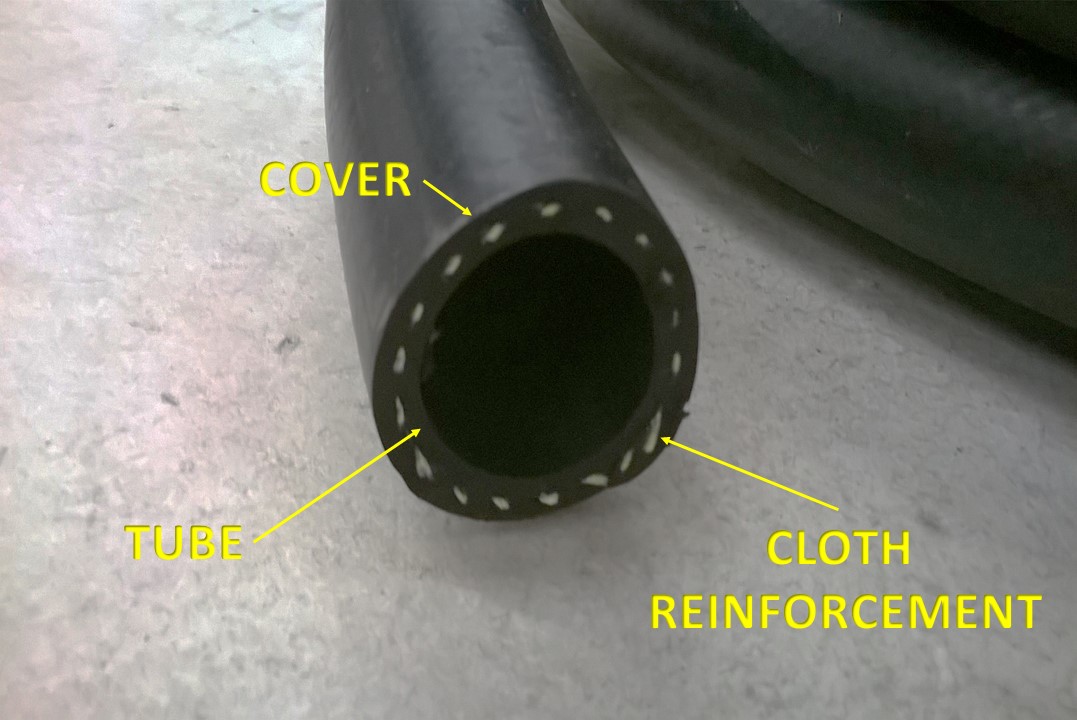

Construct the Hose Assembly Correctly- A hydraulic hose has a three-part construction: tube, reinforcement, and cover. The inside tube is a rubber compound that transports the fluid being conveyed. Reinforcement refers to a less flexible braided wire that wraps around the tube. The surrounding cover offers final protection from outside elements and adds strength to the hose. Typically, fittings are placed on both ends of the hose which are then used to connect the hose to the machine in use. When constructing the hose assembly, ensure the following-

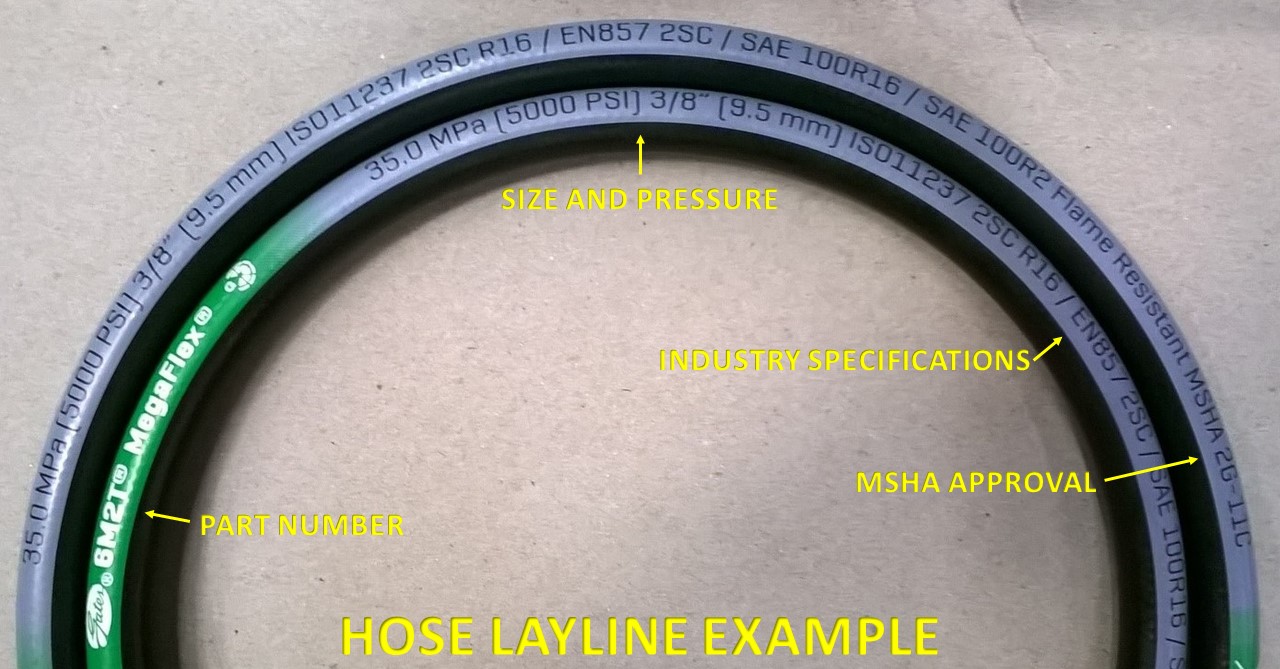

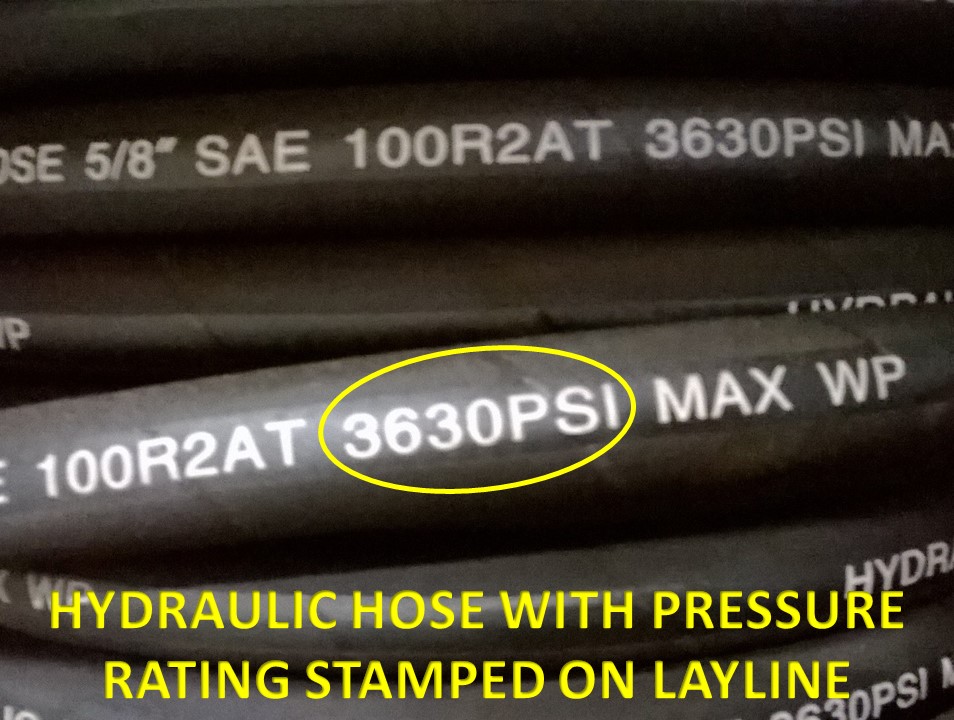

Most manufacturers will list hose identification information on the layline of the hose. Always double-check that the hose being considered is the correct length and diameter for the particular application in question.

Another good rule of thumb is to always follow the manufacturer’s recommendation for correct assembly construction- namely, using the proper fittings designed to work with the correct hose needed.

Before crimping the assembly, be sure the fitting is pushed on the hose all the way to prevent the end from blowing off during operation.

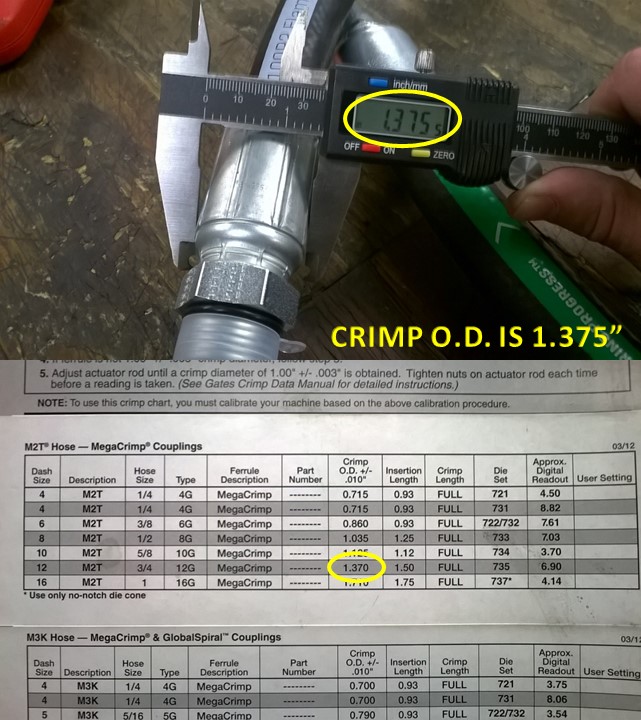

Be sure to use the proper specs when crimping the end form to the hose. Under-crimping can cause the end to blow off during operation, and over-crimping can crush the hose blocking fluid and weakening the construction. Crimping errors might not always be visible to the naked eye, so always check the crimp specs with a caliper before approving the finished product.

Step 2:

Route the Hoses Properly- Once the hose is correctly assembled it is ready to be put back in the field. Routing refers to how the hoses are positioned in regard to the design of the equipment to which they are attached. Improper routing can cause abrasion to the hose, weakening its structure. Further prevent weakening by using clamps and pivot points to keep the hose from rubbing against the machine. Use of 45 degree or 90 degree fittings might be necessary to route more efficiently.

Step 3:

Use an Appropriate Bend Radius- Maximum bend radius information for a hose is also provided by the manufacturer and should be followed to improve routing capabilities. The bend radius needs to be kept as large as possible to avoid any flow restrictions as well as prevent the hose from flattening or kinking. Allow for some slack on the length of the hose to counterbalance movement caused by the pressure of the fluid moving through the system.

Step 4:

Be Mindful of Extreme Temperatures- Another way to prevent or delay hose failure is to consider the effects that extreme temperatures can have on the life of an assembly. There are two types of extreme temperatures: Ambient and Operating. Ambient temperature refers to factors outside the hose that can cause damage during operation. Very high heat sources from the machine being used or others around it can cause weak spots in the construction of the hose. This is where proper routing techniques are essential. The hose should be kept distant from hot parts of the mechanism and any additional places where extreme heat is present. If this is unavoidable, heat resistant sleeves are available for further protection. Operating temperature refers to the maximum allowed temperature of the fluid being transferred. Any liquid too hot for the hose’s specifications can degrade the rubber tube from the inside.

Step 5:

Maintain Proper Operating Pressure- The last, but certainly not least, important way to prevent hose failure is to avoid moving fluids at or above the operating pressure of a hose. Continuous use of hoses at maximum pressure can lead to blowouts and cause leaks. Be aware that some hydraulic systems are also susceptible to dangerous pressure surges. If this is the case, consider using a hose with a higher than required operating pressure rating for normal constant flow. Pressure rating information is also normally listed on the layline of the hose.

Hose assemblies will eventually fail, but delaying the process can save time and money and minimize downtime on the job. Following these vital steps is an effective strategy to keeping hydraulic hose assemblies strong for the duration of their service life.

Shop our hose and hose fitting products

Need help?

Contact your Royal Brass and Hose local sales representative or call 800-669-9650 to speak with a member of our Customer Service team at any of our locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY)