Selecting the right sealant for temperature-specific applications is a crucial decision in various industries. Whether you're working on an automotive engine, a refrigeration system, or any application where temperature variations are significant, choosing the appropriate sealant can make all the difference. In this blog, we'll delve into the world of LOCTITE® low temperature and high temperature sealants, exploring their unique properties, applications, and performance characteristics to help you make an informed choice for your specific needs.

In this blog:

Understanding Low Temperature Sealants

Low temperature sealants are designed to withstand extreme cold conditions. They are formulated to provide a strong and durable seal in environments where temperatures can drop significantly. Here's what you need to know about low temperature sealants.

-

Features of Low Temperature Sealants: Low temperature sealants are formulated to remain flexible and effective in frigid environments. They are resistant to cold temperatures, ensuring they won't crack or lose their sealing properties when exposed to freezing conditions.

-

Temperature Range and Performance Capabilities: These sealants typically operate within a range of -60°F to 300°F (-51°C to 149°C). This wide operating range makes them ideal for applications in cold storage units, refrigeration systems, and outdoor equipment exposed to winter conditions.

-

Applications and Industries: Low temperature sealants find their utility in various industries, including the food industry (for sealing cold storage facilities), HVAC (heating, ventilation, and air conditioning systems), and transportation (for sealing refrigerated trucks and containers).

Low temperature sealants available at Royal Brass and Hose

The following LOCTITE sealants are effective in an operating temperature range of -54°C to +149°C:

Exploring High Temperature Sealants

In contrast, high temperature sealants are engineered to endure extreme heat and maintain their sealing integrity. Here's what you need to know about high temperature sealants:

-

Features of High Temperature Sealants: Formulated to resist the effects of intense heat, including exposure to flames and direct contact with hot surfaces, high-temperature sealants are designed to maintain their strength and sealing properties under extreme conditions.

-

Temperature Range and Resistance to Heat: These sealants are capable of withstanding temperatures ranging from 450°F to 2,400°F (232°C to 1316°C), making them indispensable in applications like exhaust systems, furnaces, and industrial ovens.

-

Applications and Industries: High temperature sealants excel in industries such as aerospace (for sealing rocket nozzles), automotive (for exhaust systems), and manufacturing (for sealing high-temperature equipment and machinery).

High temperature sealants available at Royal Brass and Hose

-

LOCTITE Red RTV Silicone Gasket Maker: Operating temperature range -75°F to +600°F

-

LOCTITE Black RTV Silicone Adhesive Sealant: Operating temperature range -65°F to +450°F

-

LOCTITE Black Silicone Sealant: Operating temperature range -65°F to +450°F

Key Differences Between Low and High Temperature Sealants

To choose the right sealant for your application, it's crucial to understand the key differences between low and high temperature sealants:

-

Temperature Resistance and Operating Ranges: Low temperature sealants are suitable for cold environments, while high temperature sealants are designed for extreme heat.

-

Flexibility and Adhesion Properties: Low temperature sealants remain flexible in the cold, while high temperature sealants maintain their integrity under high-temperature conditions.

-

Performance Considerations for Specific Applications: Selecting the right sealant involves considering the temperature requirements of your application, substrate compatibility, and performance expectations.

Factors to Consider for Sealant Selection

When selecting a sealant, consider the following factors:

-

Temperature Requirements of the Application: Determine the temperature range your application will be exposed to and choose the appropriate sealant accordingly.

-

Compatibility with the Substrate and Environmental Conditions: Ensure that the sealant is compatible with the materials it will be in contact with and the surrounding environment.

-

Longevity, Durability, and Performance Expectations: Consider the expected lifespan of the sealant and the level of performance you require.

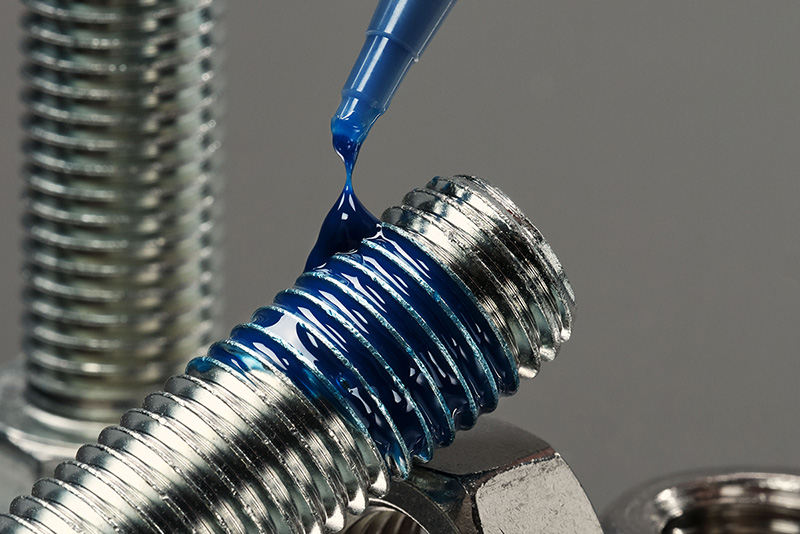

Best Practices for Sealant Application

To ensure a successful seal, follow these best practices:

-

Surface Preparation and Cleanliness: Clean and prepare the surfaces to be sealed properly to promote adhesion.

-

Proper Application Techniques and Curing Process: Follow the manufacturer's instructions for application and curing to maximize sealant performance.

-

Storage and Handling Recommendations for Sealant Longevity: Store sealants as per the manufacturer's recommendations to maintain their integrity.

Conclusion

Understanding the unique properties, temperature ranges, and application suitability of LOCTITE sealants is essential. By choosing the right sealant for your specific needs, you can ensure the longevity and reliability of your sealing projects. We encourage you to explore to find the perfect solution for your application. Make the right choice, and your seals will stand the test of time, regardless of the temperature extremes they face.

Need Help Selecting the Right Sealant?

When it comes to sealants, we’re trusted experts. Contact us or call 800-669-9650 to speak with a member of our customer service team at any of our 11 locations (Knoxville, TN; Marietta, GA; Orlando, FL; Charlotte, NC; Little Rock, AR; Fort Worth, TX; Benton, IL; Madisonville, KY; Princeton, WV; Birmingham, AL; Calvert City, KY).